What is the Most Delicious Rice?

“We will always cook more delicious rice than the previous year.” The electric rice cooker & warmers of Zojirushi, which has such a motto, are renewed in some area or another every year. The cornerstone of such development capability is the staff members specializing in basic research. They work diligently on technological research for practical application many years into the future.

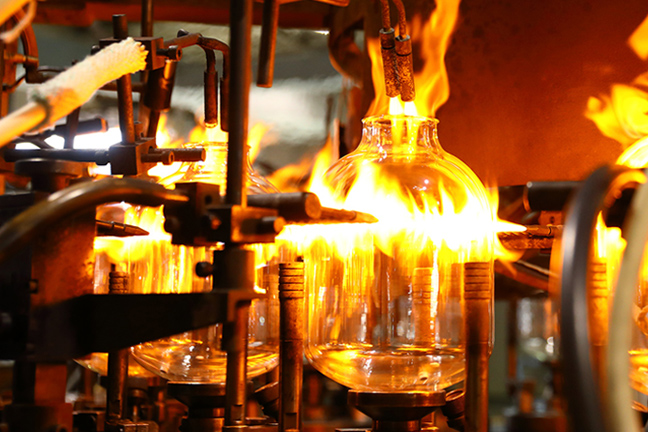

Zojirushi marked its 100th anniversary in 2018. We wanted to create something unprecedented as a product worthy of commemorating the anniversary. It triggered the momentum to aim for new deliciousness by changing the heat power rather than the inner cooking pan that had been thoroughly researched. In fact, we already knew that the convection that occurs within the inner cooking pan makes rice delicious. By creating a better heater that serves as the heat source, we should be able to create a larger convection. This was where the basic research we had been building up came in. However, changing the heater, which had been the norm for many years, required us to be prepared for a considerable risk.

New Heat, New Possibilities

“Can we really succeed?” To dispel such concerns, the research staff manually reworked the heater model again and again. Through much trial and error, we increased the number of heaters from one, which had been the constant and conventional number ever since IH electric rice cooker/warmers were invented, to three, and perfected a system in which each heater operates separately. It turned out that heat moved like the flickering flame in a hearth, and resulted in convection currents that were better than we had expected.

So, we got through the first stage. However, this was not all we had to do to make rice delicious. The baton for this challenge was passed from the research staff to the developers of the rice cooking programs. They design the programs to cook the most delicious rice by choosing the best timing to turn up and turn down the heat in units of seconds. The number of heat power combinations had increased by an order of magnitude as the number of heaters had increased to three. While it is a tedious and time-consuming process of cooking rice and then eating it, new possibilities for deliciousness are hidden in this process.

Comparison of IH Heaters at the Bottom of the Main Unit

(Above) Our conventional model NW-AT10 in 2017

(Above) Our conventional model NW-KA10 in 2018

(Above) Our conventional model NW-LA10 in 2020

Judging Deliciousness through Data and People

“Isn’t the deliciousness of rice subjective?” Some people may feel that way. At Zojirushi, the value of deliciousness is measured by both “scientific data” and “human senses,” or in both digital and analog values. This measurement method is also an important top secret in product development. As data, we measure “softness,” “stickiness,” and “sugar content” using precision instruments through collaboration with universities. By clarifying the scientific basis, we aim to manufacture products that our customers can be fully convinced of.

It is the program developers, also known as the “keepers of deliciousness,” that are mainly in charge of tastings. Since the results naturally become more accurate as more people eat the rice, employees outside of the team also help with the tasting. It probably never happens in other workplaces that you can get to eat rice by saying, “Can I help you with that job?”

(Above) Taste testing by development staff

(Above) Plate used for taste testing

Ensuring Safety Along with Deliciousness

The menu includes a variety of white rice cooking options such as “normal,” “firm,” and “soft,” as well as brown rice and rinse-free rice menus. We conducted a spectacular trial & taste process that consumed approximately 3 tons of rice in six months, where normally a total of 4 tons would be cooked in a year, to complete the full array of rice cooking programs. In the background, prototypes of the main unit, which would be equipped with the completely new heaters, were also developed.

The most important thing is to be able to deliver products that cook delicious rice for all customers, even when we manufacture tens of thousands of units. We also reviewed the design again and again to ensure that the greater number of heat sources and increased heat power would not cause a risk of burning or spills. While pursuing deliciousness, our top priority is not just deliciousness but also safety and security. This is Zojirushi’s belief for its electric rice cooker & warmers, and this will never change no matter what else does.

The Best Result of Our Efforts is the Most Delicious Rice

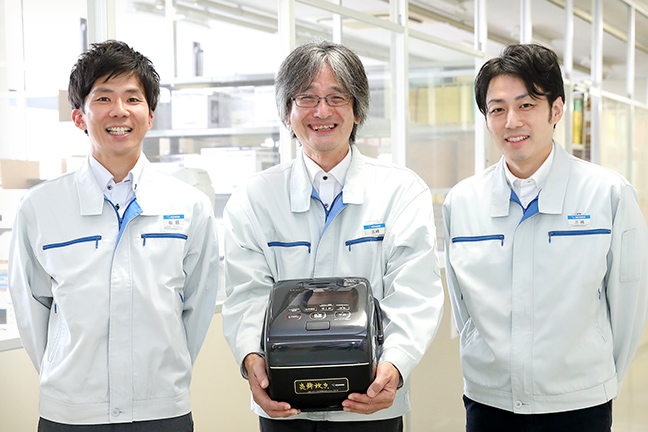

After clearing many challenges, mass production finally began. All the staff let out an “ahhh” after eating rice cooked with the same finished product that would be delivered to the customer. This was because it was clearly more delicious than “Nambu Iron Kiwame Hagama,” which had been the top-of-the-line model at the time.

What was particularly different was the plumpness and elasticity of each grain. The sweetness and umami of the rice that spread in the mouth as soon as biting into it. In line with our expectations, “This is going to be a hit!” the market response to the product has been quite positive, and we have received many pleased comments from customers who have purchased the product.

(Above) Embudaki (NW-LB) released in 2021

(Above) The plumpness and elasticity of each grain.

Continuing to Tackle the Never-Ending Challenge

Just because we developed the best electric rice cooker & warmer, does not mean that we have reached our goal. “Embudaki” has been further improved, and the latest model is even easier to clean. We continue to evolve the product into a more attractive one. Of course, other manufacturers are following suit, but increasing the number of heat sources to many times the conventional number is tough in terms of both technological ability and cost, and should not be easy to replicate.

Among the numerous electric rice cooker & warmers available, our customers continue to choose our products. It is with such pride that we enjoy the never-ending challenge, even as we say, “It is going to be tough again.” Although it is a high-end product, we are confident that you will never regret purchasing it because of the deliciousness. We hope to have as many people as possible experience it.

World Wide

World Wide

“Just-Between-Us Story”

in Manufacturing at Zojirushi

“Everyone, including my superiors and subordinates, are very serious people, so it is hard for me to keep working as hard as I can [laughs].”

Jun Misaki, in charge of research

“But they are not uptight. They are flexible enough to jump across teams to help out if something goes wrong.”

Tetsuo Funakoshi/person in charge of rice cooking flow

“I think it is the attitude of considering the problems of familiar people living their lives that is so serious, rather than coming up with outlandish ideas.”

Kazunori Mishima, in charge of product planning

The departments and contents of this document are as of the time of the interview (October 2021).