A New Answer to Food Loss

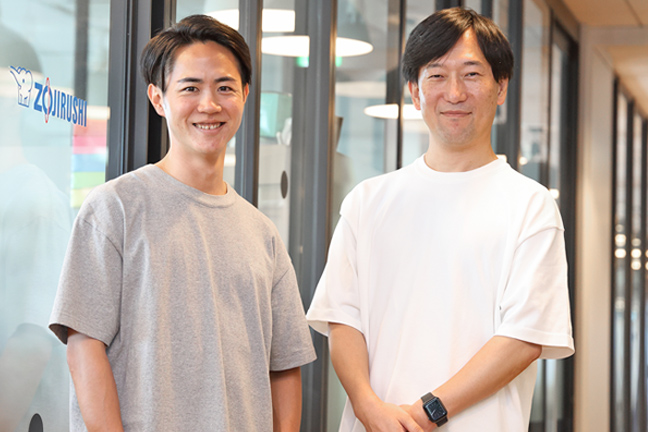

We are both initial members of the New Business Development Office, which was established in 2018. From the very beginning of the office’s establishment, we have been asking ourselves, “What can a company like Zojirushi do for society through food and lifestyles?” and examined it from multiple perspectives. Among other things, we felt that reducing food loss was an important theme for a company involved in the food industry. In the case of Zojirushi, we repeat the tasting process many times during in-house testing when developing electric rice cooker & warmers, and there was always some rice that we could not eat. We therefore decided to start working on that first.

Of course, uneaten rice has always been recycled as fertilizer for agricultural products. However, upcycling it into something new and valuable was more difficult than we expected. The solution to this problem came from an encounter with a certain company.

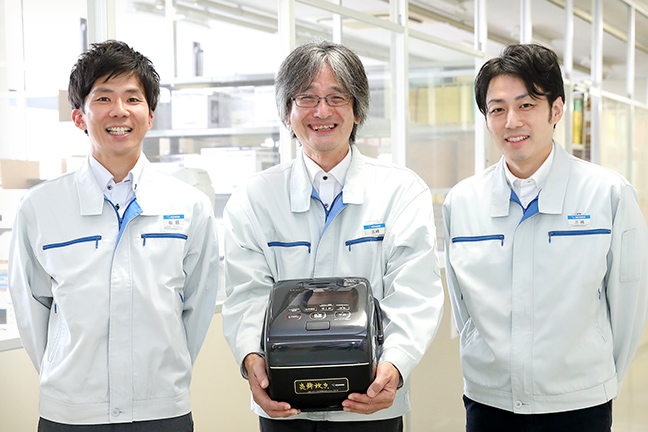

(Above) Repeated rice tastings during the development of electric rice cookers & warmers

(Above) Rice that was left because there was too much was recycled as fertilizer for agricultural products

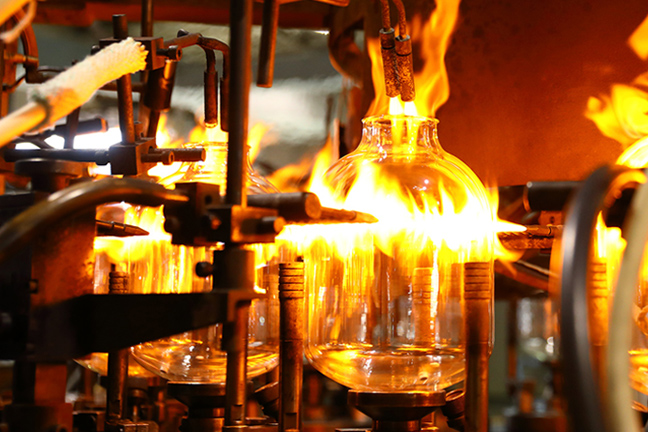

Ethanol Produced from Rice

In terms of upcycling and how to proceed with new businesses, Zojirushi, which has long been dedicated to manufacturing, did not have the know-how in-house. Then let’s learn from outside the company! This is why we joined the Innovator Development Program. It was there that we met Fermenstation, a company that has been successful in businesses such as “producing ethanol from food using proprietary technology.”

It agreed with Zojirushi’s desire “not to waste rice” while persisting with the principle of “tasting to pursue the deliciousness of electric rice cooker & warmers,” and readily agreed to our offer of cooperation. Our first attempt to make Sterilizing Wet Wipes with ethanol refined from our rice had taken off in a big way.

An “Unprecedented” Press Release Providing a Tailwind

While we were convinced, “this is exactly what Zojirushi should produce,” Sterilizing Wet Wipes were too far removed in category for Zojirushi, which had always manufactured household appliances. There were many hurdles to overcome in order to commercialize the product, including the establishment of a management and delivery system that had not existed before. What was particularly vexing for us was that we had no idea how to market the product, and to what type of target customers. The breakthrough we came up with was to send out a press release before we started making the products.

In the past, Zojirushi always released information only after a product had been completed. But this time, we really needed to know in advance what reactions there would be from the people in which field. Some were concerned about the “unprecedented nature of the project,” but when we actually made the press release, we received a wide range of responses and feedback that could be used as a reference for sales promotion and sales activities.

Cooperation Among Different Departments in Creating New Routes

Empowered by the press release, development finally began. We checked the product quality by closely exchanging data with Fermenstation, our collaborator. What was more difficult was how to maintain the “wet” quality, an aspect we had never handled ourselves before.

Actual investigation revealed the wipes tend to gradually dry out when stored in the same manner as household appliances and stainless steel bottles in existing company sites. After consulting with the logistics department, we therefore decided to store them in an air-conditioned facility. In addition, the Accounting Department taught us about the “mechanisms of distribution” and “sales management,” and the Sales Department advised us on pricing. With the cooperation of various departments, we were able to overcome hurdles one by one and create a new product flow from scratch.

Pleased with the Voices Saying “Nice”

Since we sent out the press release, we received encouraging words from other companies such as “It is a good initiative” and “The design is so cute that I want one.” In addition, the companies that have actually adopted the product as a novelty have expressed their gratitude, saying “It provided us with an opportunity to talk about the SDGs with our clients that we took the product to.” All of these are pleasant reactions that we could not have obtained without taking on the new challenge.

However, the truly difficult part is yet to come. In order to keep it alive as a new business, we need to create more opportunities to promote our products and expand our sales channels. Keeping in mind the lesson from the preceding entrepreneurs, “Start with a small step,” we will expand our connections at ecology-related events and strive to make our products available to as many people as possible.

Maintaining Our Appreciation of Rice Into the Future

In the development of this product, we placed importance on the eco-friendly image in various aspects, including softening the wording of the concept and using earth colors for the main colors of the package. We hope that Zojirushi’s attitude toward the environment and society will reach everyone with the subtle sweet aroma of the wipe when it is pulled out of the package.

More rice can be utilized effectively as more people use these Sterilizing Wet Wipes. In addition, we hope to utilize not only the rice from the tasting, but also the rice that could not be eaten inside and outside the company through new routes, including the permanent rice restaurant ZOJIRUSHI ‘GOHAN’ RESTAURANT operated by Zojirushi. Because we are constantly considering the deliciousness and importance of rice, we would like to continue our efforts to use every last grain of cooked rice with care.

World Wide

World Wide

“Just-Between-Us Story”

in Manufacturing at Zojirushi

“We are often considered ‘old-fashioned’ and ‘conservative’ by other companies, but we at the New Business Development Office would like to convey the new aspect of Zojirushi with our ‘spirit of challenge’ and ‘sincerity’!”

Miwa Kurisu, New Business Development Office

“The more people within the company express concerns about new initiatives, the more I realize that the company is sincere in its desire ‘not to disappoint its customers.’”

Yuhei Iwamoto, Manager, New Business Development Office

The departments and contents of this document are as of the time of the interview (May 2022).