Becoming a Unique Entity in Japan While Continuing to Manufacture

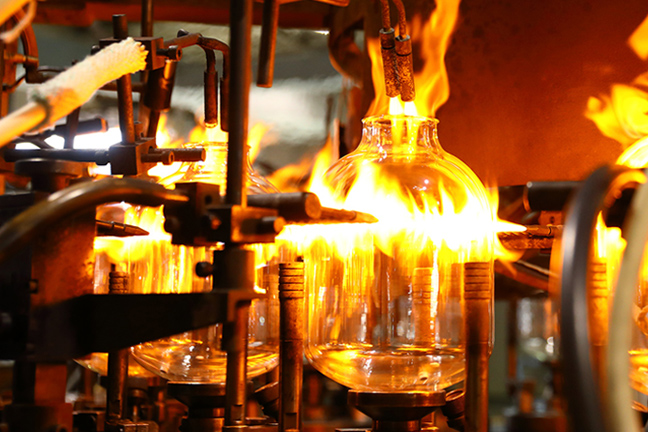

Among the sites of “Zojirushi Factory Japan,” the Fukumachi Factory, a group company responsible for the manufacture of Zojirushi products, is a production base that specializes in glass vacuum bottles.

The number of domestic factories producing glass vacuum bottles has steadily decreased over time. Even so, we have continued to produce our own products because we have customers who demand them. Now that ours is the only factory of its kind in Japan, I feel that this factory itself is a valuable asset not only to Zojirushi, but also to the history and future of glass vacuum bottle made in Japan. The wide variety of Zojirushi products and services now available all began with this glass vacuum bottle. It is our pride that we are still making the products that were the starting point of our business.

(Above) Thermal carafe assembly (1953)

(Above) Products using inner glass bottles

Glass Vacuum Bottles that Cross the Ocean

By the way, who do you think the glass vacuum bottles that are manufactured at Fukumachi Factory are delivered to? Actually, approximately 70% of the customers live overseas. Mainly for export in the first place since the establishment of our business, when thermal carafes were still high-end products in Japan. Even though they have become an everyday item and stainless steel is now the mainstream, there are people who still want Japanese-made glass vacuum bottles not only in Japan but also across the ocean.

They are especially popular in the Middle East, where coffee culture is closely connected to daily life, and in Europe and the United States, where people are very particular about the safety of what they put in their mouths. Although we have developed oriental designs and collaborated with European designers to suit the taste of each country, Japanese designs, or “Japanese patterns,” have been more popular than oriental designs.

Aiming to Also Be Unique in Terms of Quality

In addition to design ingenuity, what we value above all else is quality that can live up to our customers’ trust in “Made in Japan” or “Made by Zojirushi.” What is required here is not just the performance for keeping things warm or cold and durability. In order to meet overseas standards, which are sometimes even stricter than Japan’s in terms of comfort and safety of materials used, we have made various efforts at the production site.

A European-design product developed in 2019 highlights “Vacuum liner made of Japan premium glass” and “made of medical grade glass” in large letters on the stylish-looking packaging. This is an expression of our will to maintain quality that meets expectations as the only company that manufactures glass vacuum bottles made in Japan, starting with the inner glass bottles.

(Above) “Japanese patterns” that are popular overseas

(Above) Packaging of a European-design product

Placing Importance Even on a Single Screw in Our Machines

In the factory that supports the high quality that only Zojirushi can offer, machines that are more than half a century old are still in full operation. In order to keep using such historic facilities, attention to detail and meticulous efforts are important. For example, a single broken screw on one of the machines lined up in the factory may be a discontinued product where a replacement is not immediately available. It means that the entire production line would come to a halt because of just one screw.

That is why we stay sensitive to the maintenance and inspection of the machines, and check their operation to ensure that even the slightest abnormality is not overlooked. We conduct careful maintenance so that breakdowns and other problems can be addressed before they happen. Furthermore, where repairs are absolutely necessary, we ask the engineers at other Zojirushi factories and subcontractors to repair or restore parts. With the help of various people, we continue to protect this valuable production line.

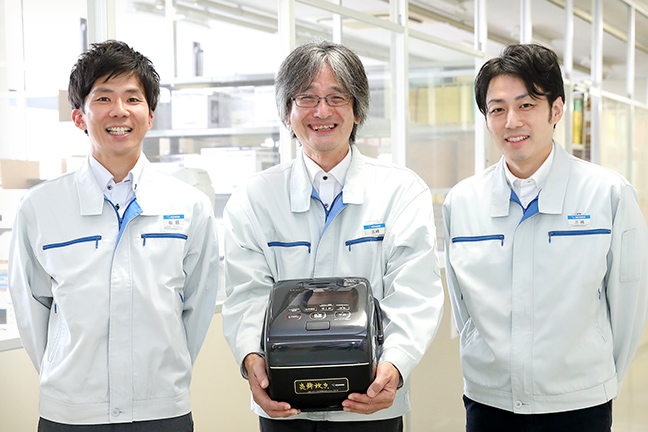

Fostering the Next Generation of Manufacturers

Of course, no matter how much we take care of our machines and facilities, we will not be able to pass on manufacturing skills to the future unless there are people to inherit them. At this Fukumachi Factory, we also focus on the succession between engineers who are responsible for the production site.

The most difficult part of making inner glass bottles is adjusting the heat when welding the glass. There are many situations where the engineer’s senses and judgment are required, such as considering the temperature and humidity of the day, which can never be left to a machine. It is impossible to transfer such skills that are learned through experience overnight. That is why we actively train young engineers. We hope to pass the baton on to the next generation by making each job worthwhile and, above all, by letting them know the joy of “creating one-of-a-kind products.”

Keeping the Glass Fire Burning

Now, more than 100 years after the establishment of our business, thermal carafes are no longer the expensive commodity they once were. They are displayed in stores along with stainless steel vacuum carafes to give customers more choices, “so that they can choose whichever they prefer.”

However, no matter how times change, our commitment will never change. Even if they are not in the majority, as long as there are customers who say “glass is better,” we hope to continue to provide products that satisfy them. Forever warm, forever cold. We intend to continue to pass on such magic of glass vacuum bottles and the history of Zojirushi’s craftsmanship.

World Wide

World Wide

“Just-Between-Us Story”

in Manufacturing at Zojirushi

“We hope to continue to offer our customers more choices by developing products that combine our 100 years of tradition with new technologies.”

Hisashi Kobayashi in charge of design and development

“While the prices of the products we manufacture vary from high-end electric rice cooker & warmers to thermal carafes, our commitment to quality remains the same. I want to continue to create products that will please our customers.”

Jun Maruyama, Fukumachi Factory

The departments and contents of this document are as of the time of the interview (March 2023).