What Zojirushi Can Do to Reduce Plastic Waste

In addition to developing products that are useful in our daily lives, Zojirushi is also involved in projects that help solve social issues. In recent years, we have been particularly concerned about the problem of plastic waste, which is becoming more and more serious around the world. Since the establishment of the New Business Department Office in 2018, we have been looking for ways for Zojirushi to contribute, and promoting activities that “encourage more use of MyBottle to reduce the use of disposable containers.”

What we recognized through these activities and surveys was that many people “own MyBottles but only use them occasionally.” A closer look at their reasons revealed that there were three major obstacles to the use of MyBottle: “washing,” “carrying,” and “preparing the contents.” Among these, we believed there was something we could do to help in the area of “washing.”

From an Encounter at a Trade Show to Co-creation

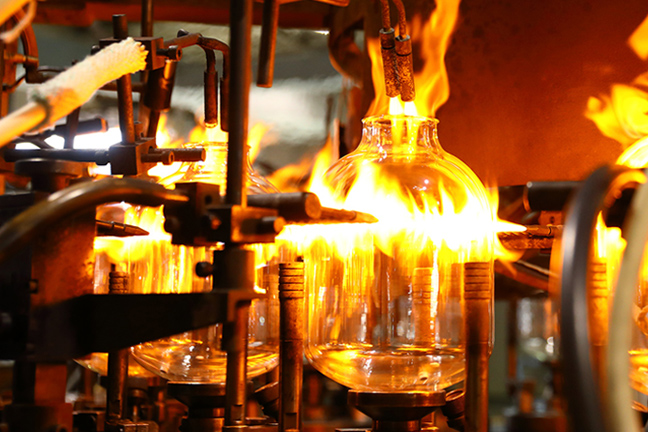

"How can we help people wash MyBottles” when they are not at their own homes has been a frequent topic of discussion in our past activities. First, we decided on the general framework of “whether to wash them all together or one at a time,” and tested this with household tabletop dishwashers and other similar appliances. It was around this time that I happened to see a parts washer from NAKANO PRECISION, a precision parts processor, at a trade show. We were impressed by the system that quickly washed and dried mass-produced factory parts, and immediately consulted about the development of a MyBottle Washer. They were willing to provide us with technical cooperation.

However, the machines exhibited at the trade show were large washing machines designed for factories, and could not be used as they were. The first prototype was completed in 2020 by reviewing the structure and parts from scratch and downsizing the machine for MyBottle washing. We promptly installed the system within the company and conducted a test operation, and were pleasantly surprised to hear people say, “we will be really disappointed when this is gone.”

Advancing Toward Commercialization Through Repeated Improvements

By bringing the prototype up to a level where it could actually be used from the early stages of development, we were able to test the washer in a variety of locations. This allowed for opinions and results obtained in the field to be used continuously to work out solutions towards the commercialization of the washer. In 2021, we moved the testing outside of the company and conducted a pilot experiment with Kindai University, whose aim is to create a “PET bottle-free campus.”

The prototype at the university was designed to wash a MyBottle in its entirety, where we found that the work of wiping the outside of the MyBottle and the large amount of wastewater were issues. Thus, subsequent prototypes were updated to “wash only the inside” of the bottle and the lid. As the environmental impact of using detergent, the time required to replenish the detergent, and the amount of water used for rinsing were also considered issues, we made various improvements, including the use of ozone water instead of detergent in subsequent prototypes. In addition, STUFF, a company that handles everything from the design and prototyping to mass production of electrical appliances, newly joined the project to make the washer more compact for use in offices and other locations. The three companies decided to move forward with the commercialization of the “MyBottle Washer.”

▲ Demonstration experiment with Nippon Steel Kowa Real Estate (December 2023 to February 2024)

▲ Demonstration experiment with SATO Holdings Corporation and the Research Institute for Humanity and Nature (April to September 2024)

Further Leap Forward and the Challenge for Expo

Just as we were in the process of reducing the size of the washer for offices, “Co-Design Challenge Program,” a public invitation by the Expo 2025 Osaka, Kansai, Japan, became a hot topic amongst our members. The theme was “Designing Future Society for Our Lives” through the development of new goods and services through co-creation by diverse companies. As an Osaka-based company, we decided to apply with our “MyBottle Washer” project with the hopes "for Zojirushi to be involved in a challenge by an Expo that will be held in Osaka.” We were selected in March 2023 because our new idea and concept of “designing the future use of MyBottle” was highly regarded as suitable for the program theme.

As the person in charge, I was happy that the project was selected, but came under pressure to develop a new washer for the Expo in addition to the ongoing development. Nevertheless, this was a chance for people in Japan and around the world who visit the Expo to learn about our MyBottle efforts. I made up my mind to take on the challenge with everything I had.

▲ Washer installed at Expo

▲ Washer installed at Expo

Enhancing the Fun That Can Be Communicated to the World

Although both were MyBottle Washers, the indoor office model we had been developing and the Expo model, which would be installed outdoors, were completely different machines. Starting with the basic structure, there were many issues to be reviewed, including design, maintainability, and security. It was an experienced engineer who had been involved in the development of various Zojirushi products for many years that appeared in front of the team members who were being pressed to deal with these issues. Thanks to the contribution of his knowledge based on his past experience on the hardware side, other staff members were able to focus on other issues such as the software side. Even the design, which could've been any form or shape, came to fruition with a form that added a playful touch that is the uniqueness of Zojirushi. We also added a new collaborator, softdevice inc., a professional user interface developer, so that overseas customers with language barriers could also enjoy using the washer.

We are working on the final finish to the washer in the hope that visitors to the Expo venue with MyBottles will enjoy using them, and that other people will become aware of this environmentally friendly action.

Same Goal, Different Shapes and Locations

Just around the time when selection for the Expo program was finalized, MyBottle Washer for offices, which we were developing for commercialization, began full-scale testing in collaboration with various companies. That is when we realized that it was important to deploy our MyBottle Washers in combination with other companies’ beverage provisioning equipment and services, such as water servers. In order to encourage changes to society and the environment, it is necessary to transcend the boundaries of companies and industries and join forces in co-creation. Fortunately through these efforts, we learned that many companies are interested in MyBottle promotion activities, and we hope to continue to expand our circle of cooperation.

Whether the location where it is installed is the Expo or an office, our desire for it to be used remains the same. I am sure that the thoughts of everyone who uses it are also the same. May the future of the earth be more beautiful as we develop a common practice in life where we can wash MyBottle anywhere. Our challenges will continue in various forms in the future.

World Wide

World Wide

“Just-Between-Us Story”

of Zojirushi New Business

Department Office

“The Expo is a testing ground for the ‘society of the future,’ so I hope we can show a glimpse of the new future, even if it fails. I really enjoy being part of a challenge like that.”

Yuhei Iwamoto / General Manager, New Business Department Office

“Sense of stability alone does not create new excitement. Especially in the development and design for the Expo, we want to show the flexible side of ‘Zojirushi that also has a sense of fun.’”

Keito Kotani / New Business Department Office

“While I myself am usually engaged in other work, what makes Zojirushi Group unique is how employees feel easy to cooperate with each other across divisions saying, ‘would you like my help?’ I am reminded again that this is a good company.”

Hiroshi Kumagai / Legal & Intellectual Property Department (in charge of new business)

The departments and contents of this document are as of the time of the interview (October 2024).